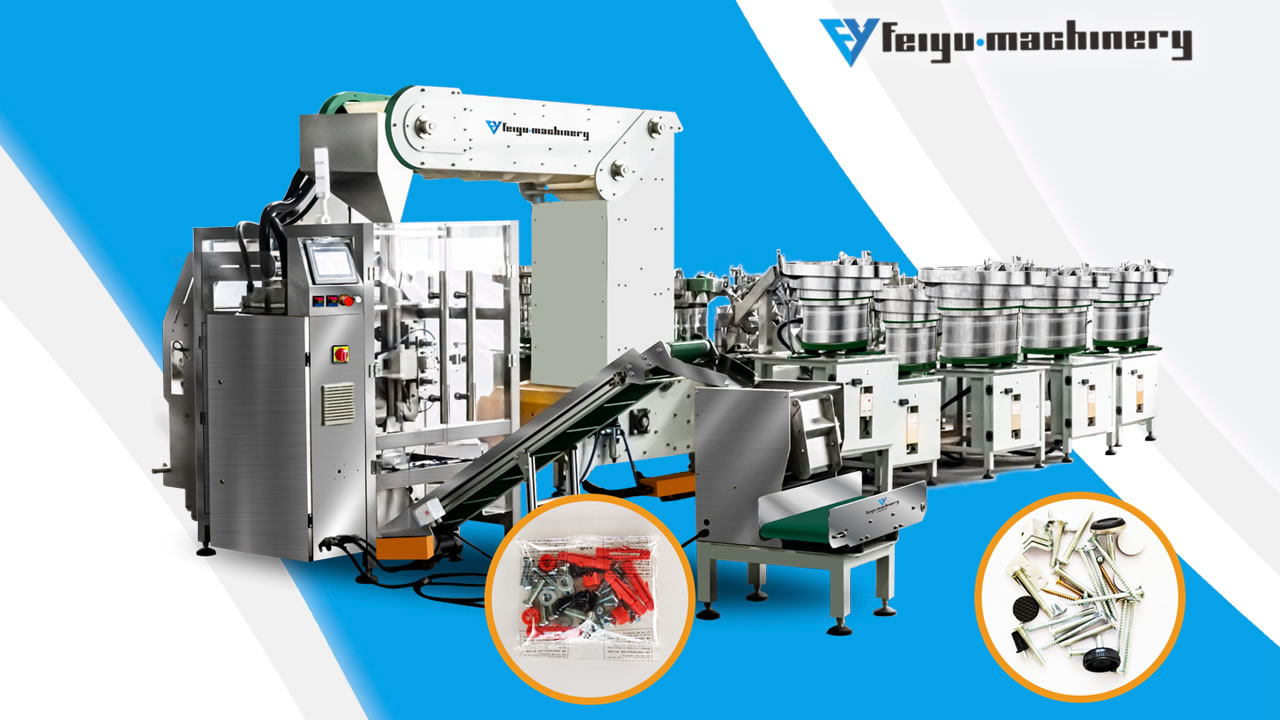

- Welcome To Shanghai Feiyu Packaging Machinery, A Leading Supplier Of Packaging Machines In China

- WhatsApp:+86-18917843031

In the fast-paced world of manufacturing and packaging, efficiency is the name of the game. And when it comes to screw packing, choosing the right machine can make all the difference. But with so many options available, how do you know which one is right for your business? Look no further – this ultimate guide has got you covered.

Whether you’re a small startup or an established industry player, finding the perfect screw packing machine can streamline your operations, increase productivity, and ultimately drive profits. But it’s not a one-size-fits-all solution. Factors such as production volume, screw type, packaging materials, and budget all need to be taken into account when making this important decision. Don’t worry though, we’ve done the research for you.

In this comprehensive guide, we’ll walk you through everything you need to know about choosing the right screw packing machine for your business. From understanding the different types of machines available to considerations for your specific needs, this guide will equip you with the knowledge to make an informed decision. So, let’s dive in and revolutionize your packaging process.

The importance of choosing the right screw packing machine

Choosing the right screw packing machine is crucial for optimizing your packaging process and ensuring the smooth operation of your business. A well-suited machine can significantly improve efficiency, reduce downtime, and enhance the overall quality of your packaged products. On the other hand, selecting the wrong machine can lead to wasted time, increased costs, and even damage to your products.

Factors to consider when choosing a screw packing machine

Before diving into the different types of screw packing machines available, it’s essential to evaluate your specific business needs and requirements. Consider the following factors to help guide your decision-making process:

1. Production Volume: Assess your production volume to determine the capacity and speed requirements of the machine. If you have high production demands, you’ll need a machine that can handle the volume without sacrificing quality.

2. Screw Type: Different screw packing machines are designed for specific screw types, such as Phillips head, flathead, or hex head screws. Ensure that the machine you choose is compatible with the screws you use in your products.

3. Packaging Materials: Consider the type of packaging materials you use, whether it’s plastic bags, blister packs, or boxes. The machine should be able to handle your chosen packaging materials effectively.

4. Budget: Set a budget for your screw packing machine investment. While it’s tempting to opt for the cheapest option, it’s important to strike a balance between affordability and quality. Remember that a reliable and durable machine will save you money in the long run.

Understanding your business needs and requirements

To further narrow down your options, it’s essential to understand your business needs and requirements. Ask yourself the following questions:

1. What are your production goals? Determine the quantity of screws you need to package per hour, day, or week to meet your business objectives.

2. What is the available space in your facility? Measure the space where the machine will be installed to ensure it fits comfortably without causing any disruptions to other operations.

3. Do you require any specific features? Consider features such as automatic feeding, counting, sorting, or labeling, depending on your specific packaging requirements.

Types of screw packing machines available in the market

Now that you have a clear understanding of your business needs, let’s explore the different types of screw packing machines available in the market:

1. Automatic Screw Packing Machines: These machines are fully automated and can handle large volumes of screws efficiently. They are equipped with advanced features such as automatic feeding, sorting, counting, and packaging.

2. Semi-automatic Screw Packing Machines: These machines require some manual intervention but can still significantly increase productivity compared to manual packaging. They are ideal for businesses with moderate production volumes.

3. Manual Screw Packing Machines: These machines are operated entirely by hand and are suitable for small-scale packaging needs. While they are the most affordable option, they have limited capacity and are not as efficient as automatic or semi-automatic machines.

Features to look for in a screw packing machine

When evaluating different screw packing machines, there are several key features to consider:

1. Speed and Efficiency: Look for machines that offer high-speed packaging without compromising accuracy and quality.

2. Flexibility and Versatility: Choose a machine that can handle various screw sizes and packaging materials, allowing you to adapt to changing product requirements.

3. Ease of Use: Consider machines that are user-friendly and require minimal training for your operators.

4. Durability and Reliability: Opt for machines made from high-quality materials that can withstand continuous use and require minimal maintenance.

5. Safety Features: Ensure that the machine complies with safety standards and has features in place to protect operators from potential hazards.

Evaluating the quality and reliability of screw packing machines

To ensure you invest in a high-quality screw packing machine, consider the following evaluation criteria:

1. Manufacturer Reputation: Research the reputation and track record of the manufacturers you are considering. Look for customer reviews, testimonials, and case studies to gauge customer satisfaction.

2. Warranty and Support: Check the warranty offered by the manufacturer and inquire about after-sales support, including technical assistance and spare parts availability.

3. Machine Testing: If possible, request a machine demonstration or visit the manufacturer’s facility to see the machine in action and assess its performance firsthand.

Comparing prices and cost-effectiveness of screw packing machines

While cost is an important consideration, it shouldn’t be the sole determining factor. Compare prices of different screw packing machines while considering the overall cost-effectiveness. Evaluate factors such as long-term durability, maintenance requirements, and potential productivity gains when making your decision.

Reviews and recommendations for top screw packing machine brands

To further assist you in your decision-making process, here are some top screw packing machine brands known for their quality and reliability:

1. Brand A: Known for their cutting-edge technology and innovative solutions, Brand A offers a wide range of screw packing machines suitable for various industries and production volumes.

2. Brand B: With a reputation for durability and precision, Brand B’s screw packing machines have gained popularity among manufacturers looking for high-performance solutions.

3. Brand C: Renowned for their user-friendly designs and exceptional customer service, Brand C’s machines are favored by businesses seeking a seamless packaging experience.

Conclusion and final tips for choosing the right screw packing machine

Choosing the right screw packing machine is a decision that can significantly impact your business’s efficiency and profitability. By considering factors such as production volume, screw type, packaging materials, and budget, you can narrow down your options and find the perfect machine for your specific needs.

Remember to thoroughly evaluate the quality and reliability of the machines, compare prices and cost-effectiveness, and consider customer reviews and recommendations. With this comprehensive guide, you are now equipped with the knowledge to make an informed decision and revolutionize your packaging process.

So, take the next step towards optimizing your operations, increasing productivity, and driving profits by investing in the right screw packing machine for your business.

Contact us to give you a comprehensive packaging solution!

© 2025. Shanghai Feiyu Packaging Machinery Co., Ltd. All Rights Reserved.